Search

Manufacturing Engineering MEng/BEng (Hons)

Study level: Undergraduate

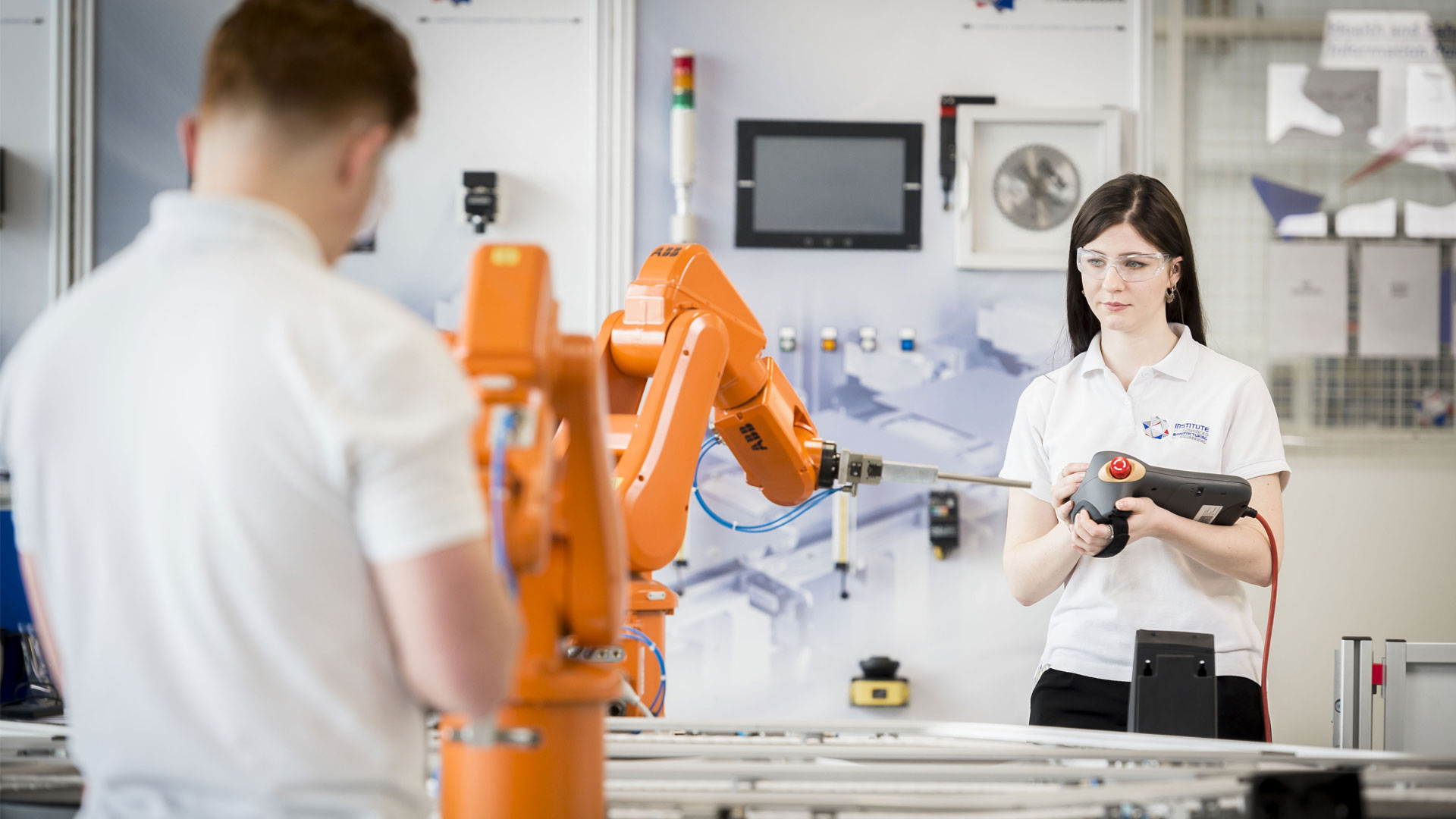

Gain hands-on experiences in robotics, automation and sustainable design, while developing technical, business and leadership skills. Learn how to design, optimise and deliver products with contemporary manufacturing technologies.

Course features

Course option

Year of entry

2026-27

Location

Coventry University (Coventry)

Study mode

Full-time

Sandwich

Duration

BEng:3 years full-time4 years sandwich

MEng:4 years full-time5 years sandwich

UCAS codes

H700 / H702

Start date

September 2026

November 2026

January 2027

March 2027

May 2027

July 2027

Course overview

Designed for ambitious problem-solvers who want to develop advanced engineering skills and creativity to drive innovation and deliver sustainable product solutions across global industries.

- Industry-led learning: work on real-world projects at Unipart’s "Faculty on the Factory Floor," gaining expertise in robotics, automation and digital manufacturing.4

- Industrial insights: gain an understanding for the challenges engineers face in global manufacturing and the steps taken to try and resolve them.

- Explore emerging technologies such as automation, robotics, digital manufacturing and sustainable product design.

- Career-ready skills: graduate with the technical expertise, leadership, and problem-solving ability to help apply for roles across motorsport, aerospace, medical, automotive, defence, consumer goods and advanced manufacturing.

Rated Gold Overall

Teaching Excellence Framework (TEF) 20235 QS Stars for Teaching and Facilities

QS Stars University RatingsTop 5 Student City in England (Coventry)

QS Best Student Cities Index 2026Why you should study this course

- Master of Engineering (MEng), an integrated master’s degree: you can join the MEng in two ways:

- Direct entry: apply straight onto the MEng if you meet the higher entry requirements.

- Transfer during your studies: if you start on the BEng and achieve strong results, you may be able to transfer onto the MEng later in your course.

- This flexibility means you could progress to the full master’s level qualification (subject to meeting progression requirements) while paying undergraduate fees.

- Live industrial projects: apply learning to mock real-world challenges each year, solving problems alongside industry professionals.

- Future-focused learning: explore sustainable design and emerging technologies that are shaping the future of global manufacturing.

- Modern facilities: access contemporary labs, simulation tools and research-led teaching at Coventry’s award-winning AME.4

- Professional development: develop leadership, teamwork and technical skills through active, social and applied learning methods.

What you'll study

Equip yourself with the technical and leadership skills needed for modern manufacturing.

Study materials, robotics, automation, lean operations and sustainable design, applying knowledge through live industry projects.

The MEng route includes advanced topics like simulation and vision systems. Blending theory with practice, this course aims to prepare you for high-demand roles across aerospace, automotive and more.

We regularly review our course content, to make it relevant and current for the benefit of our students. For these reasons, course modules may be updated.

How you'll learn

Our courses are based on a series of lectures, with tutorial sessions, associated practice, laboratory exercises and workshop exercises at both Unipart and the university4.

Teaching contact hours

As a full-time undergraduate student, you will study modules totalling 120 credits each academic year. You will normally study one 30-credit module at a time. A typical 30-credit module requires a total of 300 hours of study made up of teaching contact hours, guided and independent study.

Teaching hours

Teaching hours may vary depending on your year of study and selected modules. During your first year, you can expect 12-15 teaching hours each week. You will also have the option to attend additional sessions, including time with a progress coach or to meet with staff for advice and feedback. As you progress through your studies, teaching hours may reduce.

Guided and independent study

Throughout your studies, you will be expected to spend time in guided and independent study to make up the required study hours per module. You’ll be digging deeper into topics, review what you’ve learned and complete assignments. This can be completed around your personal commitments. As you progress through your studies, you’ll spend more time in independent study.

Online learning

As an innovative university, we use different teaching methods including online tools and emerging technologies. So, some of your teaching hours and assessments may be delivered online.

Assessment

This course will be assessed using a variety of methods which will vary depending upon the module.

Assessment methods may include:

- phase tests

- essays

- group work

- presentations

- reports

- projects

- coursework

- exams

- individual assignments

- laboratories

- posters.

The Coventry University Group assessment strategy ensures that our courses are fairly assessed and allows us to monitor student progression towards achieving the intended learning outcomes.

International experience opportunities

The University is committed to providing a global educational experience. We aim to invite international guest speakers and provide opportunities to participate in field trips and collaborative online learning experiences (COIL) where possible2.

Please note that all international experience opportunities may be subject to additional costs, competitive application, availability, and meeting applicable visa and travel requirements, and are therefore not guaranteed2.

Entry requirements

Typical entry requirements:

Not got the required grades? We offer this degree with an integrated foundation year.

Fees and funding

| Student | Full-time | Part-time |

|---|---|---|

| UK, Ireland*, Channel Islands or Isle of Man | 2026/27 fees TBC 2025/26 fees: £9,535 per year |

Not available |

| EU | 2026/27 fees TBC 2025/26 fees: £9,535 per year with EU Support Bursary** 2026/27 fees TBC 2025/26 fees: £19,850 per year without EU Support Bursary** |

Not available |

| International | 2026/27 fees TBC 2025/26 fees: £19,850 per year |

Not available |

If you choose to study this course with a professional placement2 or study abroad year, you will need to pay a tuition fee3 to cover your academic support throughout your placement year. Students commencing their professional placement in the academic year 2027/28 will pay £1,500 if they are paying UK fees, or £1,800 if they are paying international fees.

For advice and guidance on tuition fees and student loans visit our Undergraduate Finance page and see The University’s Tuition Fee and Refund Terms and Conditions.

The University will charge the tuition fees that are stated in the above table for the first Academic Year of study. The University will review tuition fees each year. For UK (home) students, if Parliament permits an increase in tuition fees, the university may increase fees for each subsequent year of study in line with any such changes. Note that any increase is expected to be in line with inflation.

If you choose to study this course with a professional placement, the University will charge the tuition fees stated above for those on a placement during Academic Year 2027/28. The University will review professional placement tuition fees each year. For UK (home) students, the University may increase fees for each subsequent year of study, but such that it will be no more than 5% above inflation.

For international students, we may increase fees each year, but such increases will be no more than 5% above inflation. If you defer your course start date or have to extend your studies beyond the normal duration of the course (e.g. to repeat a year or resit examinations) the University reserves the right to charge you fees at a higher rate and/or in accordance with any legislative changes during the additional period of study.

We offer a range of International scholarships to students all over the world. For more information, visit our International Scholarships page.

Tuition fees cover the cost of your teaching, assessments, facilities and support services. There may be additional costs not covered by this fee such as accommodation and living costs, recommended reading books, stationery, printing and re-assessments should you need them. Find out what's included in your tuition costs.

The following are additional costs not included in the tuition fees:

- Any optional overseas field trips or visits: £400+ per trip.

- Any costs associated with securing, attending or completing a placement (whether in the UK or abroad).

*Irish student fees

The rights of Irish residents to study in the UK are preserved under the Common Travel Area arrangement. If you are an Irish student and meet the residency criteria, you can study in England, pay the same level of tuition fees as English students and utilise the Tuition Fee Loan.

**EU Support Bursary

Following the UK's exit from the European Union, we are offering financial support to all eligible EU students who wish to study an undergraduate or a postgraduate degree with us full-time. This bursary will be used to offset the cost of your tuition fees to bring them in line with that of UK students. Students studying a degree with a foundation year with us are not eligible for the bursary.

Facilities

As a Manufacturing Engineering MEng/BEng (Hons) student, you’ll study at both the Engineering and Computing Building and the Institute for Advanced Manufacturing and Engineering (AME): our award-winning “Faculty on the Factory Floor”4.

Here you’ll have the opportunity to gain hands-on experience with:

- robotic automation and digital manufacturing systems: train with the tools transforming global production lines

- joining technologies and advanced simulation labs: develop expertise in welding, adhesives, and process optimisation

- metrology and product verification equipment: learn to measure and validate precision parts to industry standards

- vision systems and advanced manufacturing labs: work with the latest technology shaping Industry 4.0 and beyond.

By working directly with industry-standard tools and live projects, you should be able to develop practical skills that could give you a competitive edge in the global manufacturing sector.

Faculty on the factory floor

AME brings together academia, industry, and research and development in a ‘live’ manufacturing environment. Our collaboration with Unipart gives you the opportunity to work with some of the most talented engineering professionals in the UK.

High Performance Engineering Centre (HPEC)

Situated on the ground floor of our Engineering and Computing Building, the centre houses flight and driving simulators, a chassis design assembly and test facility, wind tunnels and a fleet of CNC manufacturing machines.

Metals Workshop

Participate in technical work in a hands-on way. The workshop includes lathes, milling machines, fabrication equipment for sheet metal work, CNC machines, work benches, welding lines and a fitting assembly area.

Facilities are subject to availability. Access to some facilities (including some teaching and learning spaces) may vary from those advertised and/or may have reduced availability or restrictions where the university is following public authority guidance, decisions or orders.

Careers and opportunities

Graduates of Manufacturing Engineering can be highly sought after across a wide range of industries. Roles may include:

- Manufacturing engineer: improving production processes and efficiency.

- Process engineer: designing and optimising manufacturing systems.

- Automation and robotics engineer: implementing smart systems on production lines.

- Quality engineer: ensuring products meet safety and performance standards.

- Operations manager: overseeing production, resources and people.

- Lean/continuous improvement engineer: driving efficiency and sustainability in manufacturing.

- Supply chain or production planner: managing flow of materials and products across global networks.

Your skills may also help you transfer into sectors such as motorsport, aerospace, automotive, defence, consumer goods, consultancy and advanced technology manufacturing.

The graduate destinations listed above illustrate potential career paths. You may need to gain additional qualifications or practical experience, pass professional examinations, complete training, cover associated costs and meet specific visa or immigration requirements to secure employment in these fields.

Where our graduates work

Successful graduates have gone on to work for Lotus Cars, Mercedes F1, Aston Martin, BAE, Meggit, Arrowsmith, Rolls Royce Aero, Quest and Unipart Group.

Further study

Discover Phoenix+

Phoenix+ brings you together with other students to learn, experience and develop essential knowledge and skills. Whatever destination you choose, it's about preparing you for life after university.

Learn more about Phoenix+How to apply

You may also like

Automotive Engineering MEng/BEng (Hons)

Mechanical Engineering MEng/BEng (Hons)